Today, the product market is highly competitive. Companies must shorten the product development (PD) cycles for their new and enhanced products to keep their edge against the competition.

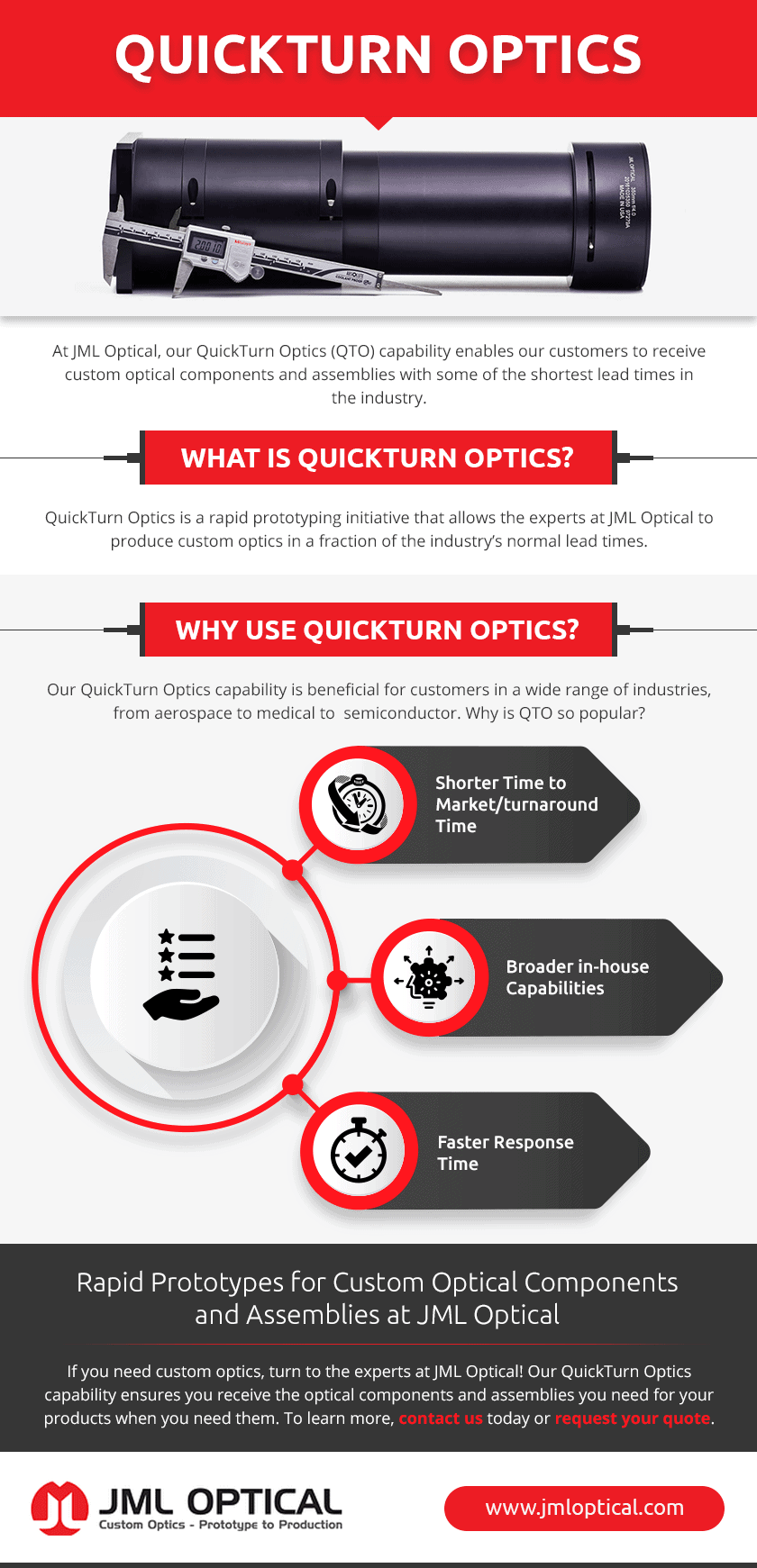

At JML Optical, our QuickTurn Optics (QTO) capability enables our customers to receive custom optical components and assemblies with some of the shortest lead times in the industry. As a result, they can prototype, test, and produce their products quicker.

What Is QuickTurn Optics?

QuickTurn Optics is a rapid prototyping initiative that allows the experts at JML Optical to produce custom optics in a fraction of the industry’s normal lead times. While it originally focused on plano and spherical lenses, we have since expanded our prototyping and production capabilities to include aspherical and cylindrical lenses and optical assemblies.

QTO combines a team of experienced opticians, a selection of state-of-the-art equipment, and a range of vertically integrated capabilities. Altogether, these elements allow us to produce and deliver engineered optical components in as little as one week and engineered multi-element assemblies in as little as four weeks from receipt of order.

Why Use QuickTurn Optics?

Our QuickTurn Optics capability is beneficial for customers in a wide range of industries, from aerospace to medical to semiconductor. Whether they need single-element lenses and mirrors or multi-element optical assemblies, they benefit from the following:

- Shorter time to market/turnaround time. Our QuickTurn Optics projects come with a standard lead time of four weeks, depending on product design and material availability. Compared to the lead times offered by other custom optics suppliers, these estimates are much shorter, enabling our customers to have shorter PD cycles and faster time to market, both of which help increase their competitive edge in their respective markets.

- Broader in-house capabilities. We perform all prototyping and production operations in-house, from engineering design to fabrication to thin-film coating to cleanroom assembly to metrology to environmental testing. This enables us to address all customer needs without wasting time and money on outsourcing operations.

- Faster response times. Our ability to produce custom components and assemblies rapidly is ideal for helping customers respond to changes in product demand. For example, during the COVID-19 pandemic, the need for medical devices and equipment rose. Our rapid prototyping capabilities helped produce components and assemblies for critical optical equipment such as confocal microscopes, microendoscopes, and optical coherence tomography (OCT) systems.