An optical lens is a transparent glass material used to bend (refract) light waves and is used to guide, control, and focus light beams. They are designed and manufactured in a variety of shapes and sizes to meet the needs of a wide range of applications, from focusing, magnifying, and shaping light beams. There are many different types of lens: spherical, achromatic, Fresnel, aspheric and cylindrical, and the utility of each depends on the end application. In this article, an overview of cylindrical lenses and their use in different complex optical instruments and systems across multiple different applications.

Cylindrical lenses are more complex than their spherical counterparts. They feature one flat surface and one curved surface and rather than focusing light to a point, a cylindrical lens focuses incoming light rays into a one-dimensional line along a specific axis. Depending on the design of the curved surface, light can be condensed, focused, or expanded as needed for a given application and type of light source. At JML Optical, we have the engineering and optical design knowledge and expertise and manufacturing capabilities to supply precision, high-quality, custom cylindrical optics in a variety of formats and sizes to meet the highly demanding specifications of numerous industries, including industrial inspection, semiconductor metrology, life science imaging, and medical instruments.

CYLINDRICAL LENSES IN THE INDUSTRIAL MARKET

Numerous industrial applications benefit from the use of cylindrical lenses. Original equipment manufacturers (OEMs) of optical instruments are increasingly using laser technology for a variety of applications, from precision metrology tools to scanning systems for optical metrology.

Laser Scanning in Optical Metrology

Laser scanning is becoming an increasingly common means of obtaining component dimensions for product design and reverse engineering. Rather than depending on manual measurements and costly trial-and-error prototype testing, laser scanning are used to focused and direct laser beams at and across the surfaces of objects under inspection. Creating laser lines rather than laser spots is accomplished using cylindrical lenses and helps ensure more surface is covered in a single scan enabling accurate measurements, even in hard to reach areas.

Laser Alignment Tools

Laser alignment tools use cylinder lenses to focus laser lines to accurately measure parts and assemblies in production settings, from the positioning of parts on aircraft, cars and trucks. Accurate component alignment ensures the safe, efficient operation of vehicles and various types of industrial equipment and, through non-contact maintenance, can help extend the service life of equipment and minimize expensive field failures.

CYLINDRICAL LENSES IN THE SEMICONDUCTOR MARKET

Cylindrical lenses are used in a variety of precision inspection systems in the semiconductor industry. Two use cases are shared here; semiconductor wafer inspection and flat panel display manufacturing.

Semiconductor Wafer Inspection Tools

As next-generation chip technology continues to advance, the feature size of computer chips is becoming smaller and more complex. To ensure that semiconductor wafers are manufactured at high yield, they are subject to rigorous quality inspections using state-of-the-art optical tools equipped with lasers (as well as non-laser illumination sources) that are guided and controlled using large spherical, aspherical, and cylindrical lenses.

In one embodiment, in brightfeld/darkfield wafer inspection systems a cylindrical lens held in a rotating mount is used to control the angular orientation of the laser spot and ensures it is held in the correct position relative to the surface of the wafer when measurements are made. In a second example, cylindrical lenses are used to create extended, one-dimensional laser lines to scan across the surface of the wafer at high speed, ensuring greater surface area is imaged in a single scan to improve wafer throughout, repeatability, accurately in near continuous operation.

Flat Panel Display Manufacturing and Inspection Systems

Flat panel displays, such as liquid crystal displays (LCD) and active matrix organic light emitting diodes (AMOLED) used in smart devices and as TV screens, are complex display technologies that require multiple process steps to manufacture them in high volume and high yield.

Laser-based process technologies are critical in the production of advanced display technologies, where laser annealing and laser lift-off steps are used at different production stages to produce the final display. Cylindrical optics, along with other large flat optics, are used to expand, form, and create homogenized laser beams to enable larger areas to be processed in a given step. In such applications, large cylindrical optics with the highest surface qualities are crucial. In addition to display fabrication, expanded, homogenized laser beams are used in inspection tools and again, precision, large cylindrical lenses are used.

CYLINDRICAL LENSES IN LIFE SCIENCES

In the life sciences instrument market, cylindrical lenses are used in a variety of different applications. We describe two examples where precision cylindrical lenses make an impact: fluorescence microscopy and flow cytometry.

LIFE SCIENCE IMAGING: LIGHT SHEET FLUORESCENCE MICROSCOPY

Light sheet fluorescence microscopy (LSFM) is an advanced imaging platform that enables precision, volumetric (3D) imaging at high speed with high spatial resolution and high signal-to-noise. LSFM is used to help understand various biochemical process in real-time, including embryonic development and mobility measurements inside living Cells.

FLOW CYTOMETRY

Flow cytometry is a technique used to detect and measure the physical and chemical properties of a population of cells or particles. The technique is routinely used in basic life science research, clinical diagnostics and, in specialized cases, used to detect contaminants in ultrapure water used in biopharmaceutical drug production. In one particular embodiment, spectral flow cytometry, two laser grade cylindrical lenses can be used to define a rectangular region rather than a focused laser spot, to spectroscopically interrogate the sample cells as they flow through a liquid stream. In cases where it is necessary to improve the quality of the one-dimensional beam, acylinders can be used to reduce the impact of aberrations and create more “clean” laser lines.

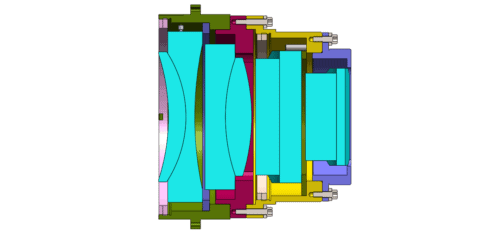

CYLINDRICAL LENSES IN ENTERTAINMENT (BROADCAST/CINEMA)

Professional motion picture camera and projection systems require high quality precision optical lenses and lens assemblies. The entertainment market demands robust housings, high-resolution image capture with low distortion over a large field-of-view (FOV), and effective and tough coatings to handle harsh, outdoor environments. Specialized cylinder lenses and lens assemblies are truly enabling optics used in this industry and enable high resolution, superior image quality and color contrast.

CYLINDRICAL LENS SOLUTIONS FROM JML OPTICAL

At JML Optical, we are committed to providing superior quality high-performance cylindrical lenses for an array of specialty applications, including industrial, semiconductor, medical, scientific, and the entertainment industry. We combine advanced CNC automated machining with traditional X-Y axis techniques to fabricate superior quality cylindrical lenses for our customers around the world.

To learn more about our extensive range of lens products and services, contact us today or request a quote.