Download Our eBook: Top Design Engineering Considerations For Optical Assemblies

Our eBook provides an overview of the considerations to keep in mind when planning the manufacture of an optical assembly.

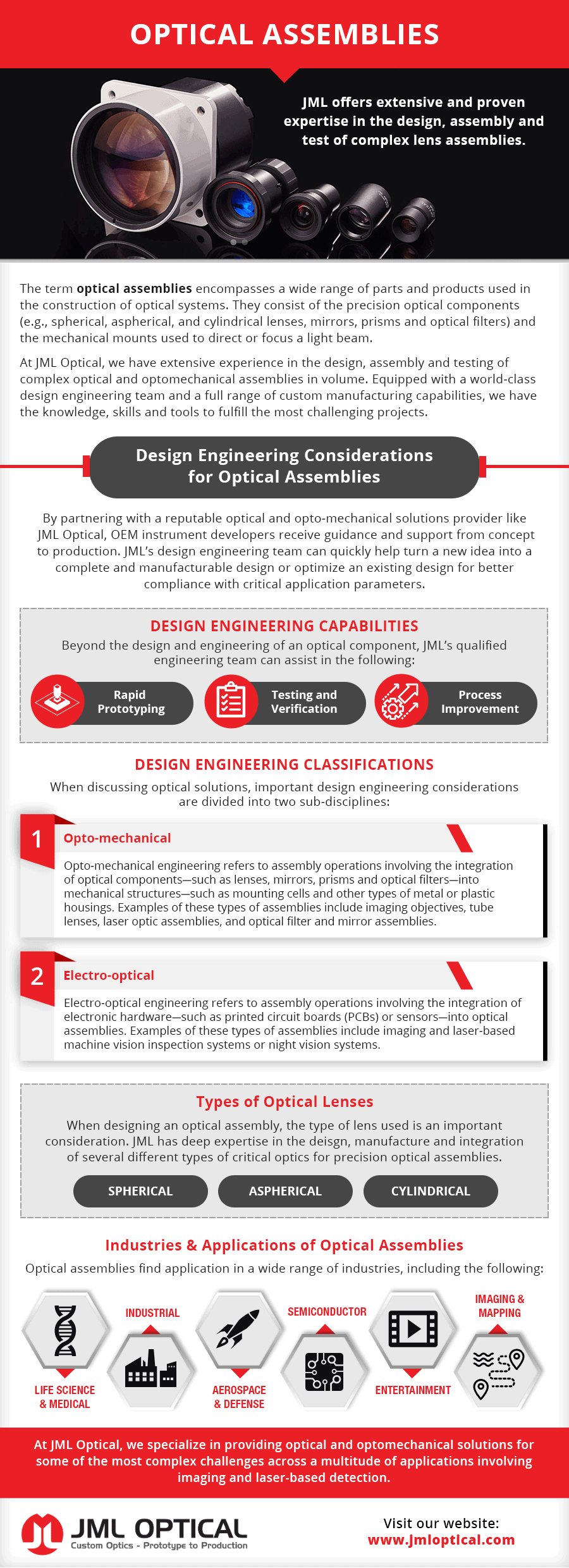

The term “optical assemblies” encompasses a wide range of parts and products used in the construction of optical systems. They consist of the precision optical components (e.g., spherical, aspherical, and cylindrical lenses, mirrors, prisms, and optical filters) and the mechanical mounts used to direct or focus a light beam. Some OEM instrument companies may find it challenging to design and engineer an optical assembly correctly. For this reason, partnering with an experienced optical and optomechanical solutions provider is key.

At JML Optical, we have extensive experience in the design, build, and testing of complex optical and optomechanical assemblies in volume. Equipped with a world-class design engineering team and a full range of custom manufacturing capabilities, we have the knowledge, skills, and tools to fulfill the most challenging projects. Below we provide an overview of optical assemblies, including the importance of working with a design engineering team when designing a new part or product, the types of optical lenses available, and the typical industries and applications where our expertise can help accelerate your new product development project.

Design Engineering Considerations for Optical Assemblies

By partnering with a reputable optical and optomechanical solutions provider like JML Optical, OEM instrument developers receive guidance from concept to production. JML’s design engineering team can assist in turning a new idea into a complete and manufacturable design or optimizing an existing design for better compliance with critical application parameters.

Design Engineering Capabilities

Beyond the design and engineering of an optical component, the team can assist in the following:

- Rapid Prototyping. Prototypes enable design engineers to discover part design or process changes that can significantly enhance product performance or manufacturability.

- Testing and Verification. The testing and verification stages ensure the finished assemblies fully comply with customer specifications before they are shipped to the customer.

- Process Improvement. Even after shipment, process engineers continue to improve upon the production methods to facilitate the fulfillment of future orders.

Design Engineering Classifications

When discussing optical solutions, design engineering processes can be divided into two sub-disciplines:

- Optical mechanical. Optical mechanical engineering refers to assembly operations involving the integration of optical components—such as lenses, mirrors, prisms, and optical filters—into mechanical structures—such as mounting cells and other types of metal or plastic housings. Examples of these types of assemblies include imaging objectives, tube lenses, laser optic assemblies, and optical filter and mirror assemblies.

- Optical electrical. Optical electrical engineering refers to assembly operations involving the integration of electronic hardware—such as printed circuit boards (PCBs) or sensors—into optical assemblies. Examples of these types of assemblies include machine vision inspection systems or night vision imaging systems.

Types of Optical Lenses

When designing an optical assembly, the type of lens used is an important consideration. Below we outline the different types of lenses available and their characteristics.

Spherical Lenses

Spherical lenses are the most used lenses in optical systems design. They feature one surface that is either convex or concave and one surface that is either planar (i.e., flat) or curved. Plano-concave spherical lenses are designed to have a negative focal length and diverge incident light, forming a virtual image. Plano-convex spherical lenses are designed to have a positive focal length and converge light, creating both focused real images and magnified virtual images.

At JML Optical, we are equipped with large plano polishers, CNC spherical grinders, and spherical polishers. This equipment enables us to accommodate high-volume orders of spherical and plano lenses, which can be integrated into an optical assembly or provided as individual pieces.

Aspherical Lenses

Aspherical lenses are lenses with a non-spherical shape and a radius of curvature that gradually changes from center to edge. When appropriately selected for an optical assembly, they can reduce the number of individual elements required and eliminate issues commonly related to the use of spherical lenses.

Cylindrical Lenses

Cylindrical lenses have a radius of curvature along only one axis. As a result, they focus light into a line rather than a point. They are often used in laser-based applications and medical applications where it is necessary to generate a single laser line for marking or scanning an object. Cylindrical lenses are also commonly used in high-end cinematography systems. Some of the types available include singlets, doublets, triplets, plano-concave, plano-convex, sphero-cylindrical, symmetric concave, symmetric convex, and acylindrical.

Industries & Applications of Optical Assemblies

Optical assemblies find application in a wide range of industries, including the following:

Life Science & Medical

n the life science and medical markets, numerous devices, equipment, and systems rely on optical components to perform their function. Some specific examples include:

- Genome (DNA/RNA) sequencing platforms

- Microscopy (imaging) platforms for cell analysis (fluorescence, white-light, phase contrast)

- Flow cytometers

- Digital PCR readers

- Neuro-imaging systems (fluorescence)

- Robotic surgery equipment

For these optical assemblies, precision, accuracy, compactness, portability, and compliance with industry standards (e.g., FDA guidelines) are critical.

Industrial

In industrial operations, the use of automation technologies in assembly and testing is growing to meet demands for better product and process quality. Optical components play a key role in the function of the systems used in such operations, including:

- Laser alignment tools

- Robotic/machine vision control systems

- Laser barcode readers

- Multispectral sensing and imaging systems

- In-line spectrometers for pharmaceutical and industrial water testing

Aerospace & Defense

In the aerospace and defense industries, optical assemblies are often found in imaging and surveillance systems, such as:

- Heads-up displays (HUDs)

- Laser guidance systems

- Periscopes/Prism viewing systems

- Range finders

- Rifle scopes

- Drone vision/imaging systems

- Security cameras

Like the medical industry, the defense and aerospace market demands precision, reliable performance, and quality above all else. Flexibility from suppliers to accommodate the ever-changing procurements standards outlined by various government agencies is also a crucial need.

Semiconductor

Semiconductor chips are a core component of numerous industrial and consumer electronic products. For semiconductor manufacturers, the primary challenge is finding a balance between the demand for increased performance and decreased size. Specialized optical assemblies—such as flat-panel display inspection, PCB manufacturing, reticle defect inspection, robotic vision control, and wafer pattern detection monitoring systems—help them achieve this goal.

At JML Optical, our precision optics are used in semiconductor wafer inspection tools. Our ability to design and manufacture coated optics up to 350 mm in diameter offers advantages for inspection systems that operate in the visible (VIS) and near-infrared (NIR) wavelength ranges.

Entertainment

In the entertainment industry, professional image capture and projection systems rely on high-quality, high-precision optical lenses. The key characteristics are durability, high resolution, and low distortion over a wide field-of-view (FOV). Examples of systems where optical assemblies commonly find application include:

- Digital movie theater projectors

- Laser projectors

- Professional-grade motion picture cameras

- Simulation and training systems

Imaging & Mapping

Imaging and mapping equipment, such as light detection and ranging (LiDAR) systems, geographic image systems (GIS), or other visual mapping technologies, rely on optical components. The components employed must be designed and constructed for durability, high resolution, and low distortion to ensure they function as intended in various environments. Some examples include:

- Ground-based and low-earth aerial imaging systems

- Space-based earth imagery (high-resolution, multi-spectral) systems

- Hyper-spectral land imaging systems

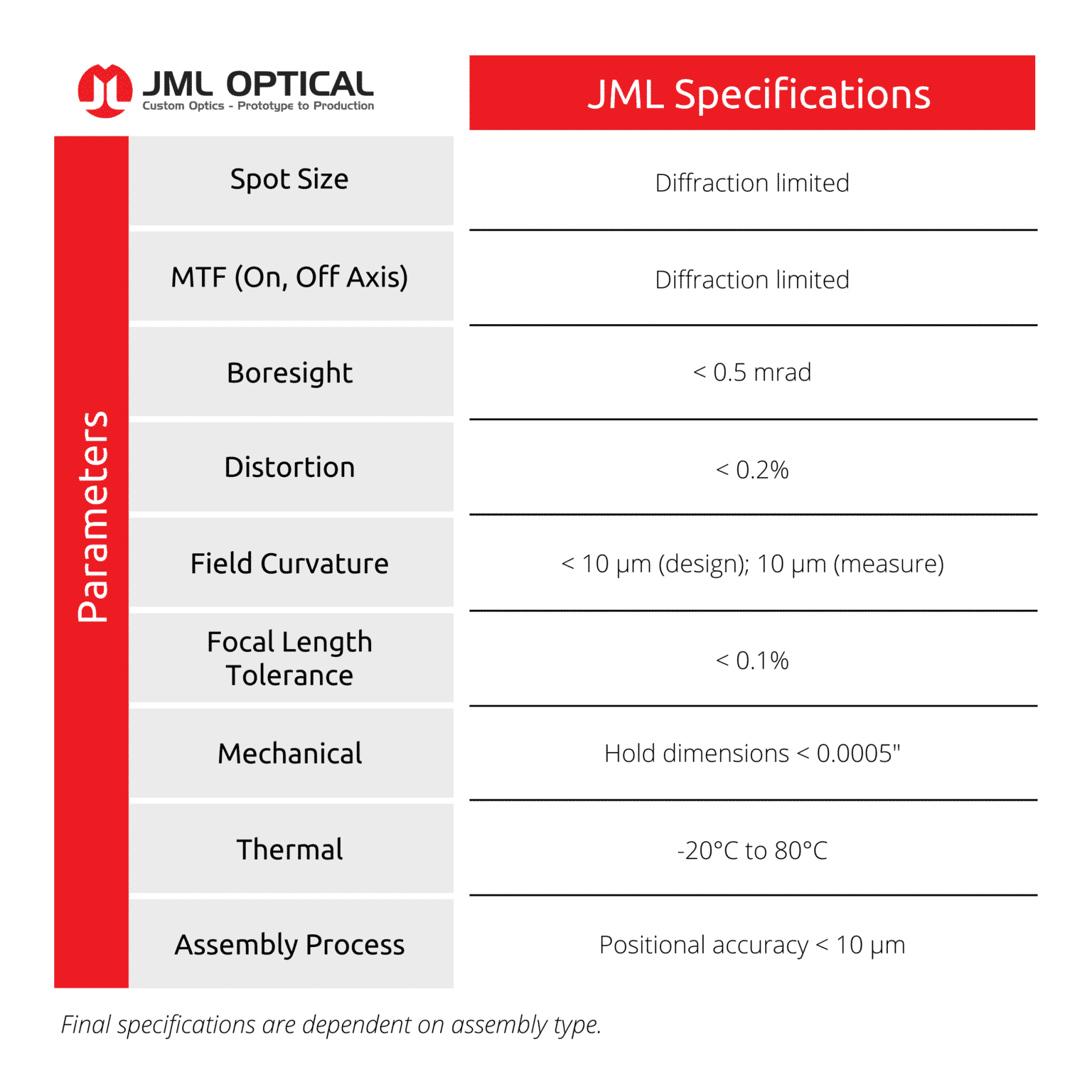

Assembly Level Specifications

JML Optical: Precision Optical Assemblies From Prototype to Production

At JML Optical, we specialize in providing optical and optomechanical solutions for some of the most complex challenges across a multitude of end applications involving imaging and laser-based detection. By partnering with us for their optical assembly needs, our customers benefit from:

- World-class optomechanical design engineering

- Extensive range of custom optics product solutions

- Industry-leading assembly and metrology equipment, including a nitrogen chamber and Class 1000 cleanroom with Class 100 Laminar flow workspaces

- State-of-the-art optical metrology equipment

- Value-added services, including thin-film protective coating and environmental testing

We accommodate customer requests for the following optical assemblies:

- Imaging objectives and tube lenses

- Lens assemblies (wide FOV)

- Doublet and triplet lens assemblies

- Intricate viewing prism and optical systems

- Fast (large aperture) lenses

- Athermal lens systems

- Focus and zoom designs

Over our decades in operation, we have honed our fabrication, assembly, and metrology capabilities, and developed an in-depth understanding of our tolerance capabilities at each stage of the process. This data enables us to make accurate predictions about product performance and manufacturability as we work with clients on design development and refinement.

Also, of note is our ability to provide professional QuickTurn Optics services. Thanks to our skilled engineering team and efficient manufacturing mindset, we can turn out complex assemblies within 4–8 weeks. We can also increase turnaround even further, when necessary. In the past, we have delivered custom components in as little as one week.

If you want a proven partner for your next optical project, start a conversation with us today.