Design Engineering

Whether it’s for a one time project or a new product development cycle our optical and mechanical designers with work directly with your engineers to meet your requirements.

Aspheres

Use our in house asphere fabrication capability to manufacture a high performing, space and weight saving optical system.

Cylinders

Our engineered cylinder cell uses state of the art equipment to bring custom cylinders to the market in days instead of weeks.

Quickturn Optics

At JML we have expanded our QTO program to now include assemblies, cylinders and aspheres.

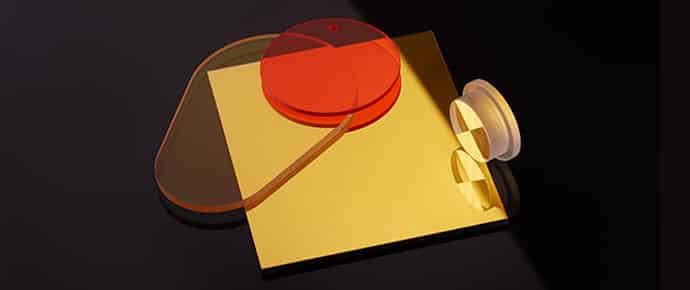

Coating

Our in house coating chambers complete our optical component product line to provide high end optics, either alone or in assemblies.

Spherical/Plano

Our in house fabrication capability encompasses almost any spherical or plano shape your system requires.

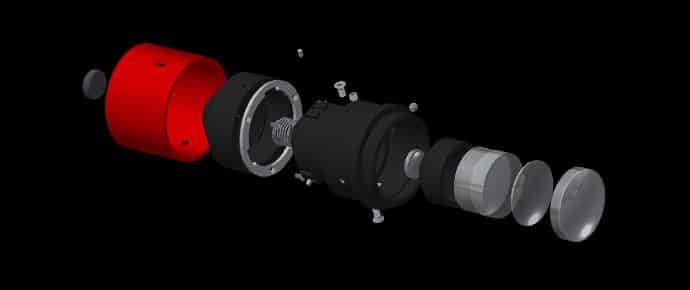

Assembly

The majority of our business today is the designing and building of complex lens assemblies. We have succeeded in the most challenging of optomechanical projects.